Reverse Osmosis Water Filter System Water Purification Machine

Drinking Water Treatment Plant

Product Introduction of RO Water Treatment System

The methods of water treatment include physical treatment and

chemical treatment.

The physical method includes the use of various filter materials

with different pore sizes, and the impurities in the water are

excluded by adsorption or blocking. The most important adsorption

method is adsorption by activated carbon, and the blocking method

is to pass water through the filter material to make the volume.

Larger impurities cannot pass, resulting in cleaner water. The

chemical method uses various chemicals to convert impurities in

water into substances that are less harmful to the human body, or

concentrates impurities. After the impurities in the water are

collected, the volume becomes larger, and the impurities can be

removed by filtration.

The Basic Working Principle of RO Water Treatment System

After a special high-pressure pump, when the raw water is added to

a pressure of 6-20 kg, the raw water permeates through the reverse

osmosis membrane with a pore size of only 0.0001 microns under the

action of pressure. Chemical ions, bacteria, fungi, and virions

cannot pass through, and are discharged with wastewater. Only water

molecules and solvents with a volume of less than 0.0001 microns

are allowed to pass through.

Technical Specifications of RO Water Treatment System

| 6000LPH Reverse Osmosis System |

| Model | JFRO-6000L |

| Host Size | 3000x800x1600mm (can be customized) |

| Power | 5.5KW |

| Power Supply | 220V /380V/460V - 50Hz/60Hz,220V 50Hz can be customized |

| Operating Pressure | 0.8-1.2MPa |

| Recovery Rate | 60% |

| Designed Water Inlet | 10000L/h |

| Outlet Flow | 6000L/h |

| Desalination Rate | ≥99.5% |

| RO Frame | SUS304 |

| Membrane Size | 8040 |

| Membrane Elements | DOW /Hydranautics/Troy/ Vontron (Optional) |

| Number of Membranes | 6 |

| Raw Water Pump | CNP/NYP/GRUNDFOS (Optional) |

| High Pressure Pump | CNP/NYP/GRUNDFOS (Optional) |

| Tank Material | SS/FRP(Optional) |

| Control Valve | Manual/Automatic |

| Control Valve Brand | FLECK/RUNXIN |

| Membrane Housing | FRP |

| Number of Membrane housing | 3 |

| Pipe Material | U-PVC/ Stainless steel (Optional) |

Advantages of RO water treatment system:

(1) pressure is the main force in RO separation process, which does

not go through the phase transition of energy intensive exchange

and has low energy consumption; (2) RO does not need a lot of

precipitants and adsorbents, and its operating cost is low; (3) RO

separation engineering is simple in design and operation and short

in construction period; (4) RO purification efficiency is high and

environmentally friendly. Therefore, RO technology has been widely

used in domestic and industrial water treatment, such as

desalination of seawater and brackish water, production of medical

and industrial water, preparation of pure and ultra-pure water,

industrial wastewater treatment, food processing concentration, gas

separation, etc.

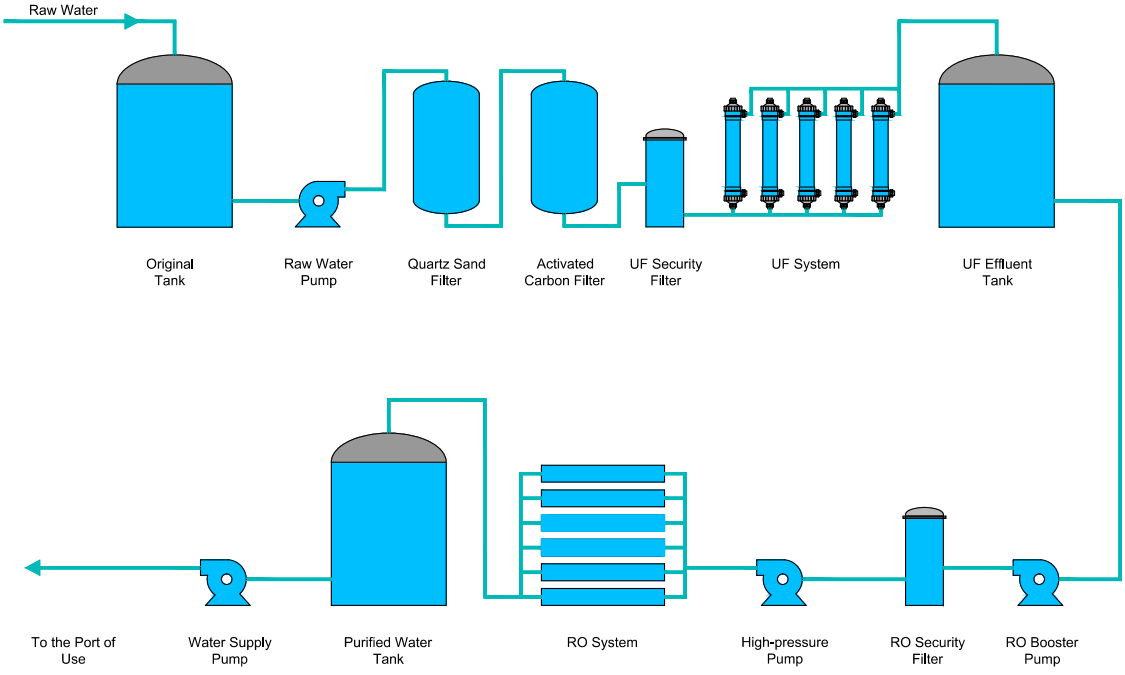

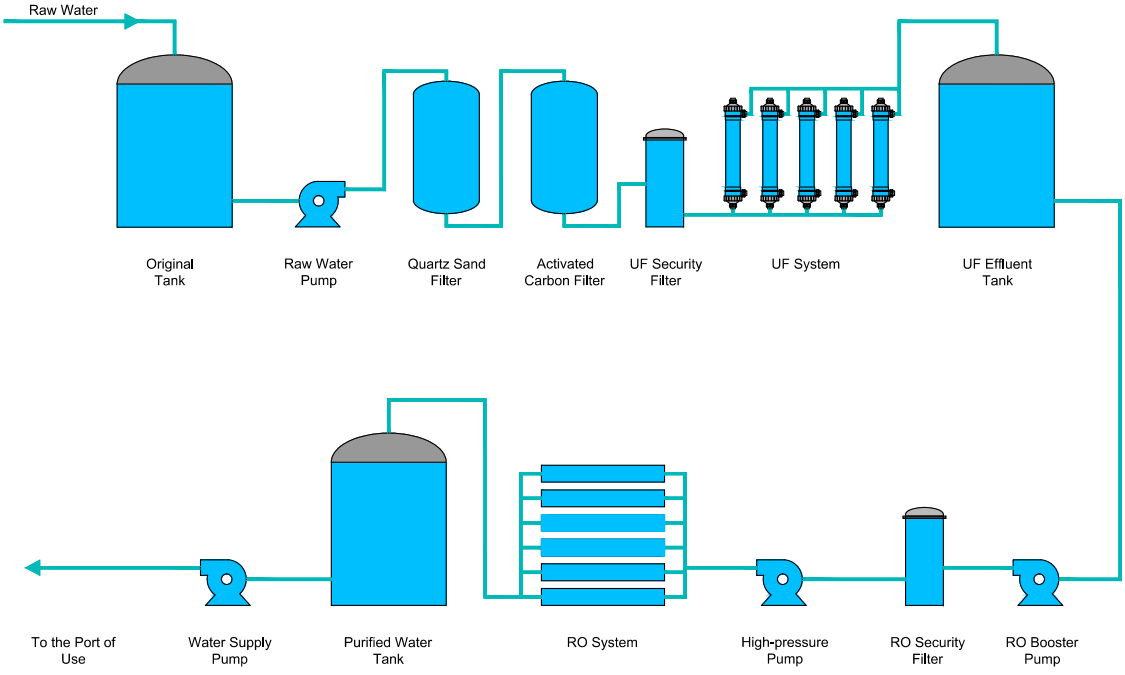

Process flow of RO Water Treatment System

Raw water pump→ mechanical filter(quartz sand filter)→ activated

carbon filter→ Water softener filter→security filter→ high pressure

pump →reverse osmosis system

1. Water tank: storage of tap water, to solve the problem of

insufficient tap water pressure and the back booster pump due to

the impact of insufficient water, reduce the failure rate

2. Booster pump: equipped with a stainless steel pump, to provide

sufficient pressure for subsequent filtration

3. Quartz sand filter: mainly remove the mud, suspended solids and

large particles in the tap water

4. Carbon filter: mainly remove organic substances, residual

chlorine and odor in tap water

5. Water softener filter: mainly remove the calcium and magnesium

in tap water, reduce the hardness of water

6. Security filter: further filtration, protection of reverse

osmosis membrane

7. High pressure pump: provide enough pressure for reverse osmosis

system

8. Reverse osmosis unit: the core part of pure water equipment, the

production of high-purity water.

9. Pure water tank: storage pure water, can change the size of the

water tank,after the below process,The water result is pure enough

for different application.

Photos of reverse osmosis water treatment system

FAQ:

1. What is the design water yield of ro membrane element? (except

anti-pollution membrane and seawater desalination membrane)

Model 4040 is designed by 0.25m3/h

Model 8040 is designed by 1-1.2m3/h

2. What is the material of mechanical filter?

Carbon steel, stainless steel, fiberglass

3.What are the multi-way control valves?

Manual control valve, automatic control valve

Multi - way control valve is divided into: filter valve and

softening valve

Automatic control valve is divided into: time type and flow type.

Multi-way control valve brands are: FLECK, AUTOTROL, Runxin, clean

source, etc.